No products in the cart.

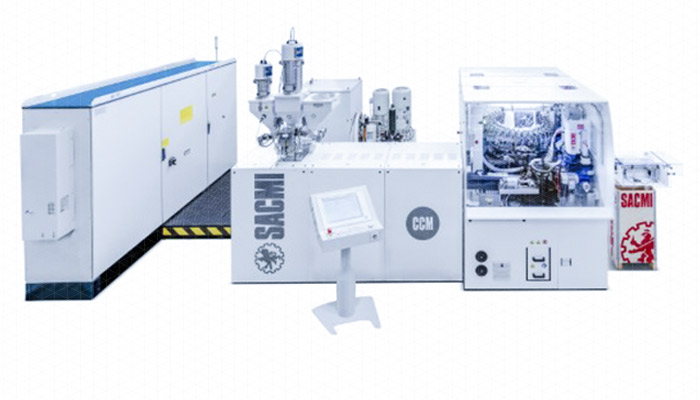

SACMI - CONTINUOUS COMPRESSION MOLDING MACHINE

Compression molding is a high-pressure molding process: the polymer is melted, mixed and homogenized inside a plasticizing unit. A device draws doses of polymer that have the exact same weight as the product and inserts them into the molds. The pressure applied to each mold can be as high as 400 kg/cm2.

ADVANTAGES OF COMPRESSION MOLDING TECHNOLOGY

HIGHER PRODUCTIVITY thanks to a shorter cycle time. The lower extrusion temperature allows the mold to cool the cap faster.

ENERGY SAVINGS due to the lower extrusion temperature. With less energy needed to heat the plastic, less is required to cool it.

PRODUCT WITH BETTER MECHANICAL PROPERTIES. Because plasticizing occurs at low temperatures and with no hot runner, the raw material maintains its characteristics and product performance is improved.

CONSTANT WEIGHT AND SIZE OF THE PRODUCT is a winning feature of this technology, exceeding the best results of injection molding. A cooler product exiting the mold means less shrinkage and therefore less size variability.